Your Current Position: News

-

2019-12-17Fluorine rubber sheet is an indispensable material in the industrial industry. Therefore, the rubber sheet should be stored carefully and carefully to avoid affecting the normal use of the rubber sheet.

-

Compared with ordinary rubber sheet, EPDM rubber sheet has improved in all aspects. The article mainly introduces the performance and characteristics of rubber sheet.

-

This article mainly introduces the extrusion properties of three common rubbers and their effects on the product, and provides methods to improve the extrusion properties of rubber.

-

Common vulcanizing media include water, air, steam, and other solid media. The article mainly introduces the effect of different vulcanization methods on rubber sheet.

-

2019-12-16The rubber sheet is widely used in many industries, and various industries have high requirements for the flame retardancy of the rubber sheet. The article mainly introduces the ways to achieve the flame retardance of the rubber sheet.

-

Adding flame retardants to synthetic rubber sheets can improve their flame retardancy. The article mainly introduces the principle, classification and development trend of flame retardant.

-

2019-12-16Most rubber products are flammable and combustible materials. By adding a flame retardant or flame retardant filler to rubber, the flame retardancy of the product can be improved.

-

The article briefly introduces the reasons for the odor produced by the insulating rubber sheet, describes the method to remove the odor, and finally introduces the method to distinguish the quality of the rubber sheet.

-

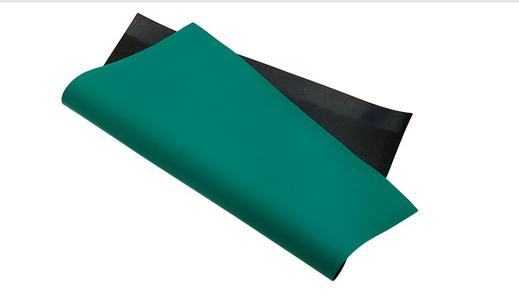

The article introduces the manufacturing process, installation steps, structural characteristics, color, performance characteristics, and size of antistatic rubber sheets.

-

2019-12-12Rubber seals are the most common sealing element. Seals can be divided into different categories according to material, characteristics and form of movement.