Your Current Position: News

-

2021-09-27Affected by energy consumption control, carbon neutrality, and other factors, the prices of natural gas, electricity, raw materials, etc. have risen across the board. Please reconfirm the prices before placing orders.

-

Glass wool and rock wool, as important thermal insulation materials, have their own characteristics and advantages in terms of production technology, production performance, and product use.

-

2019-12-19The manufacturing process and performance of different EPDM products are different. Special attention needs to be paid to the suitability of custom EPDM products in order to purchase qualified products.

-

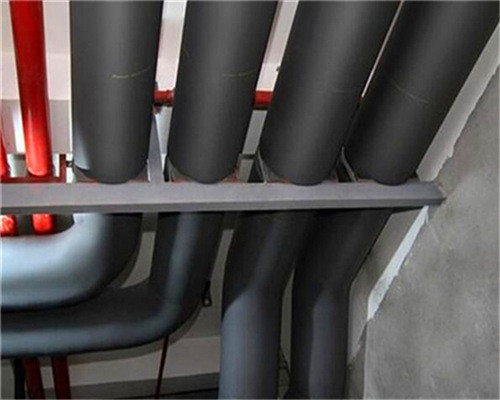

2019-12-19Foamed EPDM is a synthetic material with complete saturation and high flexibility. It is widely used in many industries such as automotive and construction engineering.

-

The combustion grade of insulation materials is divided into A grade, B1 grade, B2 grade and B3. There are different performance characteristics of insulation products with different combustion grades.

-

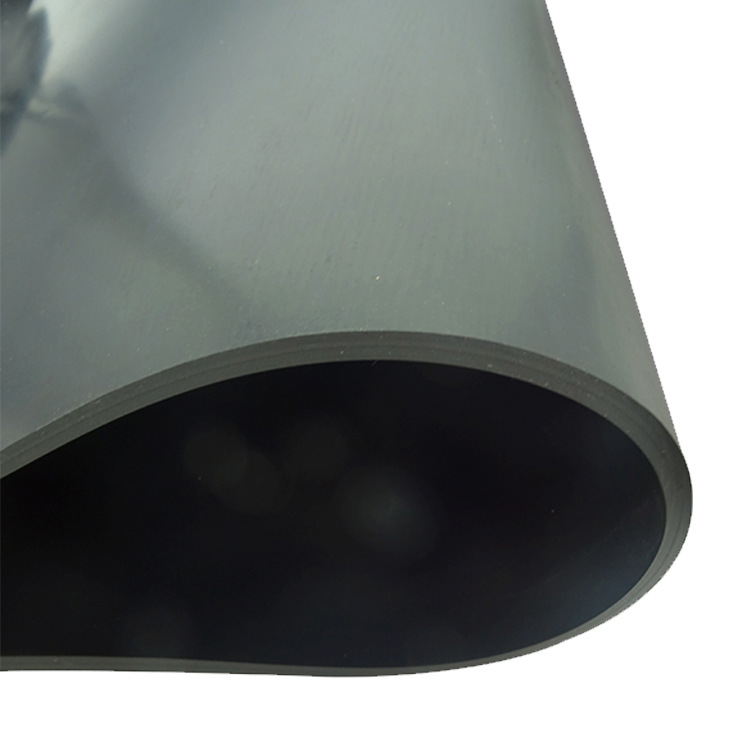

During the construction of rubber and plastic boards, glue needs to be used for fixing and bonding. In the process of using glue, correct methods and steps need to be adopted.

-

WRP-105 rock wool board exterior wall insulation system has excellent heat insulation, fire prevention, sound insulation, noise reduction and crack prevention characteristics. It is currently a relatively advanced fire insulation system.

-

2019-12-18The article introduces the matters needing attention when sticking and installing rock wool boards, and construction should be carried out in accordance with relevant operations and requirements to ensure construction quality.

-

This article mainly introduces the manufacturing method of rock wool board adhesive. It should be noted that the adhesive is time-effective and must be used within a specified time.

-

In the construction of external wall rock wool board, it is necessary to consider whether the construction conditions are qualified to ensure the quality and progress of the construction.