Your Current Position: News

-

This article briefly describes the rubber sheet symbol, the way the rubber sheet is packaged, the shipping and storage methods, the storage temperature and humidity range, and the best storage date.

-

2019-11-19Insulating rubber sheets are widely used in power plants, power distribution rooms, substations and other places to provide insulation and protection, but improper handling can easily cause aging and damage of rubber sheets.

-

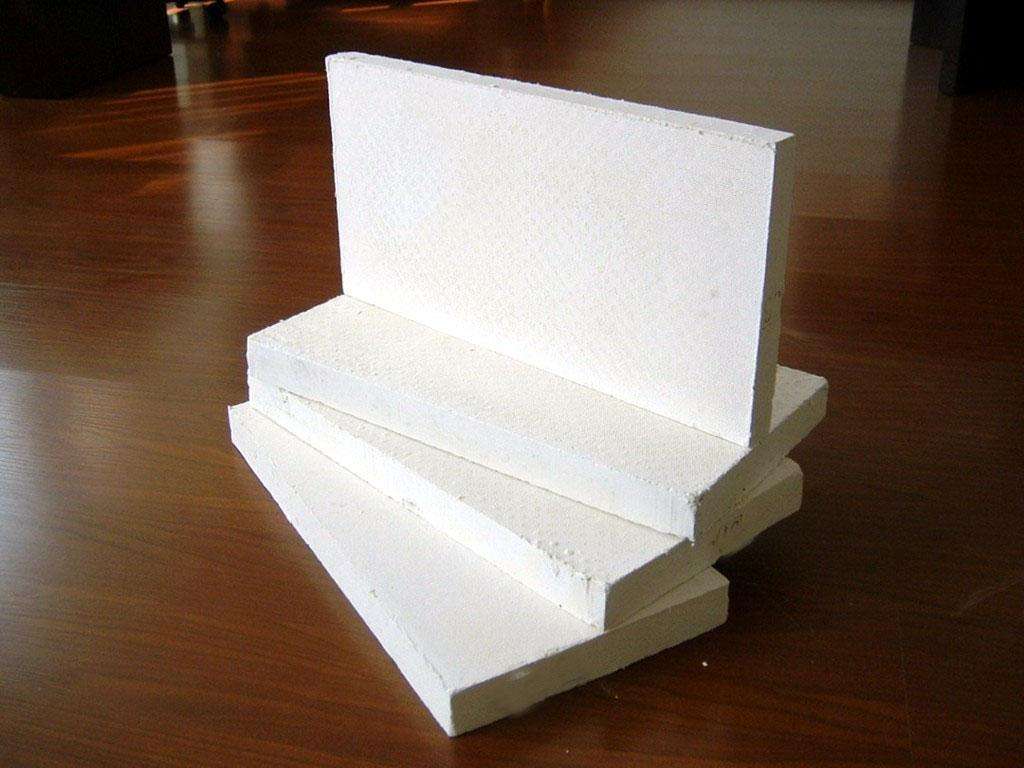

In ceramic fiber products, the main components, impurities, humidity, atmosphere, masonry, working system and fuel have a great influence on the temperature of ceramic fiber.

-

Compared with traditional thermal insulation materials, ceramic fibers have the advantages of high temperature resistance, small thermal conductivity, good thermal stability and good chemical stability. It is popular with many people.

-

2019-11-18Ceramic fiber refers to fiber with ceramic chemical composition. It is a fibrous lightweight refractory material with high temperature resistance, light weight and low thermal conductivity. It has a wide range of applications.

-

2019-11-18Waterproof materials are classified into waterproof coils, rigid and flexible waterproof materials. The article mainly introduces the composition, characteristics and functions of different waterproof materials.

-

2019-11-15Insulating rubber sheets have an insulating effect and are widely used in electric power places. Therefore, it is very important to select high-quality and safe insulating rubber sheets.

-

2019-11-15When subjected to the oxidation of ozone, the rubber sheet is prone to aging. For the protection of rubber sheets, it is generally divided into physical protection methods and chemical protection methods.

-

2019-11-15The article briefly introduces the composition and manufacturing process of silicone rubber sheet.

-

2019-11-14Natural rubber is one of the most widely used types of rubber. Natural rubber is mainly composed of proteins, fatty acids, ash, sugar and other ingredients. Various ingredients have different roles and effects.