Your Current Position: News

-

After vulcanization, rubber products need to undergo a series of post-treatments to become qualified finished products. The article mainly introduces the specific processing steps and methods.

-

2019-12-11This article mainly introduces the installation process of glass wool roll felt, and separately introduces the roof construction and wall construction methods.

-

The characteristics of the surface and internal structure determine that glass wool has an excellent sound absorption and noise reduction function, and the larger the thickness, the better the effect.

-

As a special thermal insulation material, glass wool has a wide range of applications. Double-layer insulation is required to use glass wool under high temperature conditions.

-

When using rock wool board for the external wall insulation materials , special attention should be paid to fire prevention, moisture resistance, and static electricity prevention.

-

2019-12-10The use of rock wool board in the house can enhance the house's thermal insulation performance, as well as fire, moisture and aging resistance, and improve the comfort of living.

-

In recent years, the problem of building energy consumption has become increasingly serious. The large use of rock wool boards on the exterior walls of buildings can reduce energy consumption to a certain extent.

-

The density of the composite rock wool board has a certain effect on the product's thermal insulation quality, fire rating and noise reduction effect.

-

The structure of the composite rock wool board includes an adhesive layer, a thermal insulation layer, a plastering layer, a decorative layer and accessories. The article briefly introduces the composition and characteristics of each structure.

-

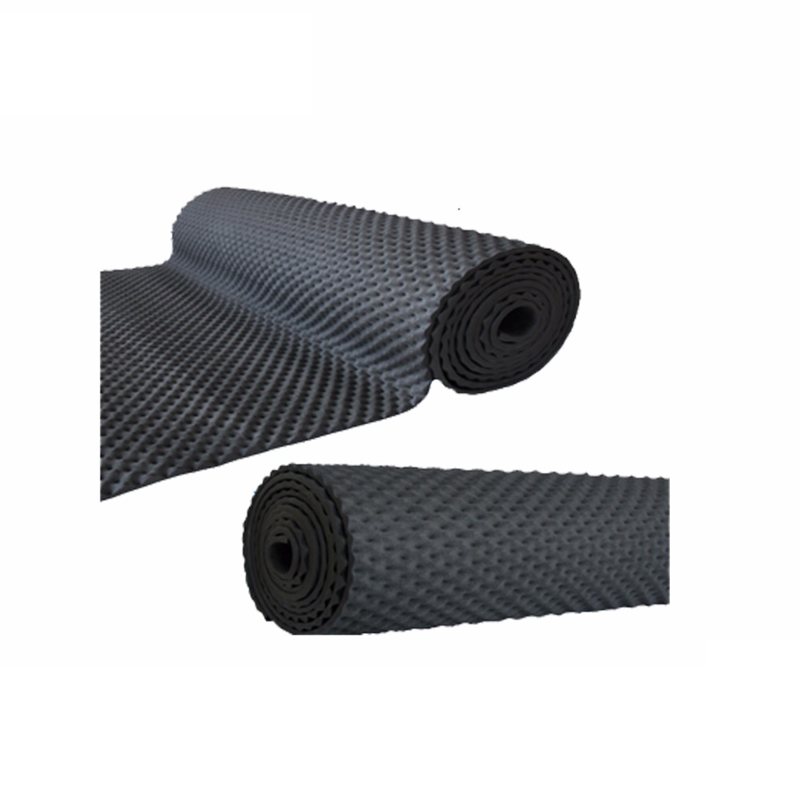

2019-12-09This article mainly introduces the repair process of anti-slip rubber sheet. The operation steps of cold vulcanization repair process and hot vulcanization repair process are introduced in detail.